Case study

Bioremediation of chromium contaminated soil and water in industrial plant

Treated Matrix

Groundwater and unsaturated zone

Contaminants

Hexavalent Chromium

Setting

Emergency Response in working industrial plant (MISO)

Treatment

In situ bioremediation with direct injection of detoxifying mixture

We performed the reclamation of a site contaminated by hexavalent chromium following an accidental spill. The bioremediation approach consisted in the in situ application of a detoxifying solution, designed specifically for this site, according to laboratory tests carried out on representative soil samples.

Prior to our intervention a pump & treat system had been active on the site: the concentration of the contaminant measured in the aquifer downstream of the pumping station was not significantly reduced at the end of three years of activity.

The bioremediation system for hexavalent chromium pollution exploits the natural capacity of some microorganisms to transform the toxic hexavalent chromium into non-toxic trivalent chromium. This is achieved by treating groundwater and/or soil with site-specific detoxifying mixtures, able to stimulate the indigenous microorganisms that naturally metabolize the pollutant via different pathways. The bioremediation technology is very versatile and effective both for site reclamation and emergency settings.

In this specific case the system was applied initially as an emergency barrier downstream of the site, drilling a line of injection wells intercepting the aquifer, that created a microbial “filter”. Subsequently, the contamination source was identified in the vadose zone and directly treated in situ with the detoxifying mixture.

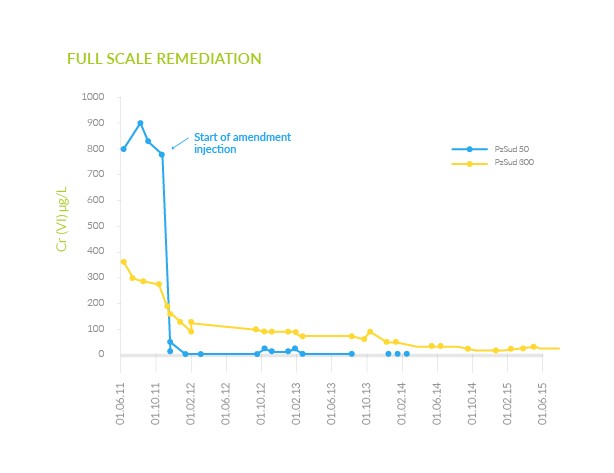

The elimination of hexavalent chromium from the site (blue line) was achieved in only 40 days: the concentration of the metal in the groundwater downstream the site dropped from the initial 900 µg/l to below 5 µg/l, the latter being the concentration limit set by the environmental regulations. The orange line indicates the concentration of Cr(VI) at a well located 300 mt away from the contamination site, which also receives groundwater effluents from nearby plating factories.