Case Study

HYDROCARBON CONTAMINATED BROWNFIELD REMEDIATION

Treated Matrix

Unsaturated zone

Contaminants

Heavy hydrocarbons

REMEDIATION TYPE

On site bioremediation: Biopile

SOIL VOLUME

26.000 m3

REMEDIATION OBJECTIVES

Industrial (column B Tab. 1 atch.5 Tit V part 4 D.Lgs 152/06. )

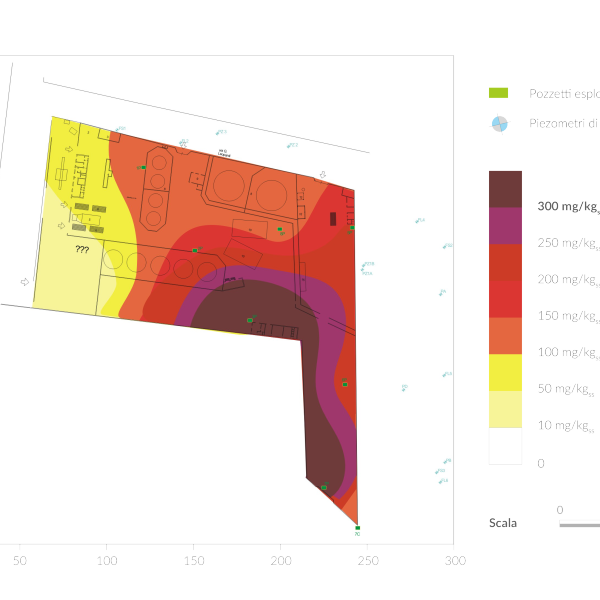

The site, with an area of 16,000 square meters, used to host various industrial activities with high environmental impact such as an oil depot and a facility for the treatment of hazardous industrial waste. These activities had a major impact on the environment and led to a massive contamination of the site .

A preliminary assessment of the technologies available for the reclamation of the site indicated bioremediation as the best solution applicable, according to the BATNEEC principle.

The choice of bioremediation technology was supported by both the feasibility study performed in the laboratory (Microcosm test), and by the field pilot test; this simulates the dynamics in the real matrix and makes it possible to determine the operating variables which can optimize the process.

On the basis of the information supplied by the preliminary tests, a biopile bioremediation approach was adopted with the construction of three biopile, for a total volume of about 26,000 cubic meters of treated soil.

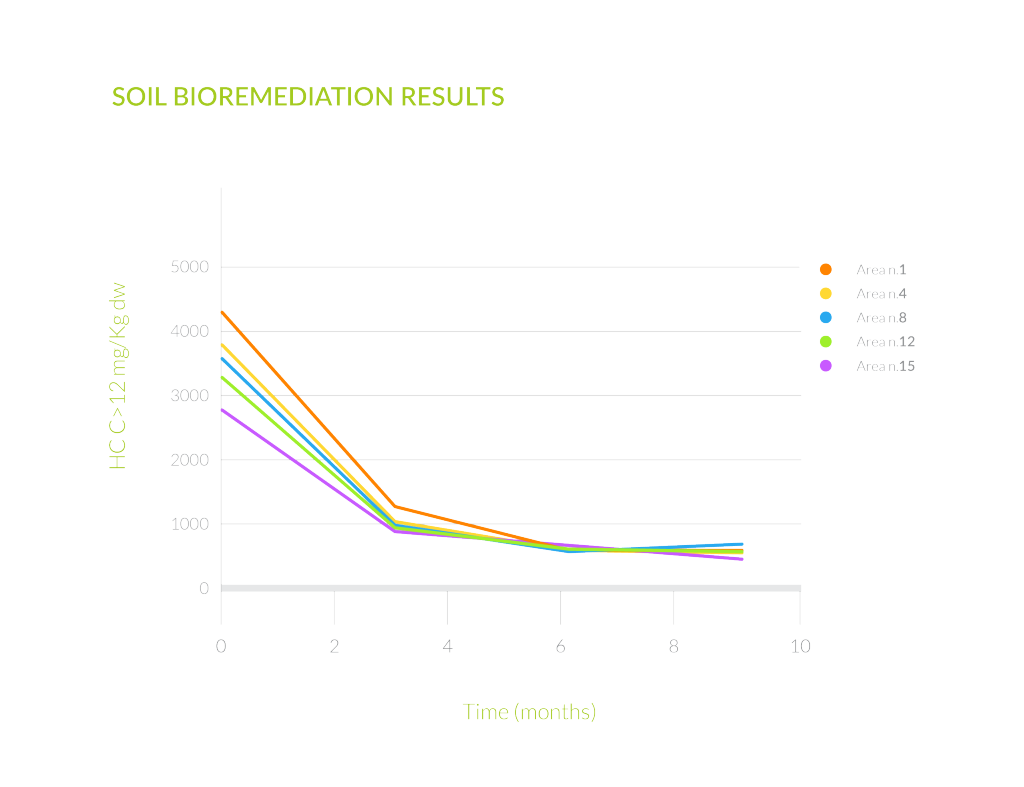

The treated soil was contaminated with heavy hydrocarbons and solvents. HC C> 12 average values were 3,000 mg/kg dw, with peaks of 15,000 mg/kg dw.

The contaminated soil was excavated and subjected to sieving; the finer fraction was mixed together with a solution of nutrients and natural biosurfactants developed to enhance hydrocarbon bioavailability and promote the growth of indigenous microflora.

The project had a total duration of about one year. The three biopiles underwent a treatment cycle of about five – six months, at the end of which the piles were gradually dismantled and the soil recycled in the backfill operations within the site. There was no disposal of contaminated soil to landfill sites.